Focus Area 2: More sustainable production methods and materials

PWT Group is aware that we have a substantial environmental footprint – and we are committed to reduce this. We want to reduce our negative impact on the environment and climate by continuously improving processes and supporting suppliers on their journey towards more environmental-friendly production methods.

More sustainable products

The most sustainable garments are quality products that will last for many years. PWT Group has worked in recent years to reduce the number of styles and gain a better quality and durability for each garment. Until now, the Group has reached a 63% reduction of styles (compared to 2017 data).

Research shows that the biggest CO2 emissions in the apparel value chain derive from material production (38 %) . Therefore, in our efforts to reduce our environmental footprint, it is essential to look at how we can shift from conventional materials and production processes to ones that leave a smaller footprint.

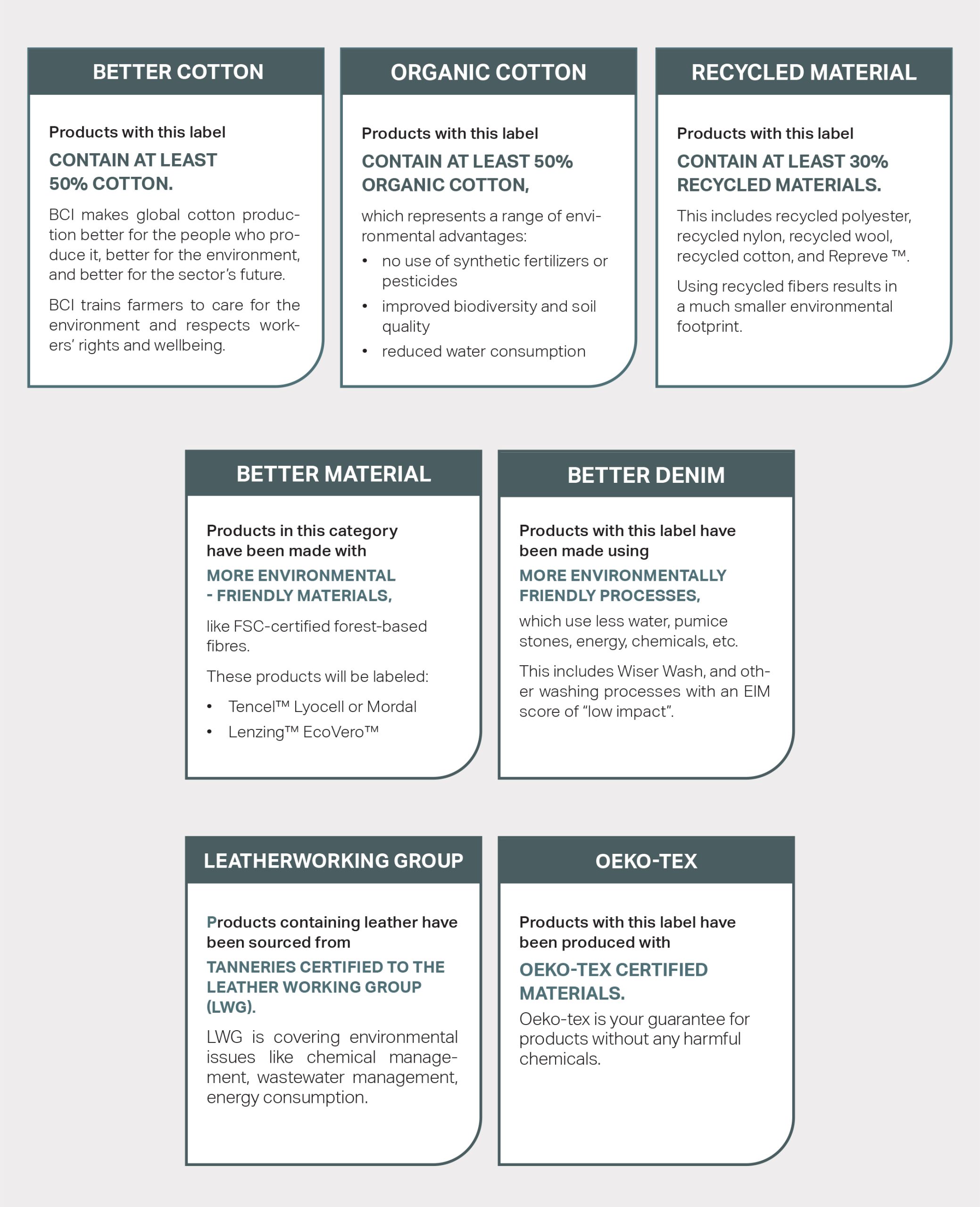

For this purpose, designers and purchasers are working with suppliers on finding more sustainable materials and production methods. The approach is to cooperate with suppliers on finding the best solution that makes sense on all parameters. This intensified focus has resulted in several initiatives, such as implementation of organic cotton, Better Cotton, recycled polyester, and better denim production.

For now, we are working with the below categories for responsibly made products.

Packaging

Since 2019, we have replaced all bags and gift boxes in our shops with ones made out of recycled materials. We are proud to cooperate with Plastic Change, the Danish environmental organization that works to break the exponential growth of plastic pollution.

Another considerable impact, when talking about packaging consumption and waste, is the packaging material used during transportation of our products, such as poly bags, tissue paper, and carbon boxes. We are continuously assessing how to reduce our use of such materials, in close collaboration with our suppliers.

Climate Reporting

From 2021, we have been measuring our carbon footprint through an online reporting system provided by Cemasys. The reporting system follows the GHG Protocol and ISO 14064, and the aim is to map our emissions and track our progress on reducing Co2e-emissions throughout our business. You can find the latest version below.

No Harmful Chemicals

We are aware of the risk of use of harmful chemicals during production, and we are actively working to avoid them, for the sake of both local biodiversity and environment and the health of the people working in production.

The Group has set up a Restricted Substances List (RSL) in collaboration with Bureau Veritas. The RSL applies to all garments and accessories manufactured for PWT Group. All suppliers must sign this document before starting production. The RSL is based on the Regulation (EC) No. 1907/2006 of the European Parliament, also known as the REACH regulation, and is updated on a regular basis. For each sales season, styles are picked out for testing at local BV labs, based on a risk assessment. Occasionally, random tests are performed from the warehouse in Denmark in order to avoid golden samples.

Further to these efforts, suppliers receive support on improving their chemical management system, through online webinars and local trainings through third parties (e.g. amfori), small trainings during visits, etc.

PWT Group has decided to certify a range of its products to the OEKO-TEX® Standard 100. This is a way to be able to provide our customers with chemical safe products, where only certified materials have been used in the production. The Group is completing its OEKO-TEX® approval process in the spring of 2021.

Animal Welfare Policy

All relevant suppliers are required to sign and comply with our Animal Welfare Policy. It states, among other things, that we only accept leather from animals bred for the food industry, that mulesing is not accepted, and that we do not accept live plucking of birds.

Introduction of amfori BEPI Program for suppliers

It is essential to look at the production methods throughout the supply chain. As we do not own any production sites, we rely on the suppliers to improve their current processes. This is a challenging area, as many suppliers lack resources and knowledge on the subject. However, as a brand, we want to support them in this process and push for sustainable changes.

We have started engaging strategic suppliers on the amfori BEPI (Business Environmental Performance Initiative) program. Through the BEPI program, suppliers are asked to report on their energy consumption, waste management, chemicals, etc. Based on this, we can assess their priority areas and support them in improving their environmental performance level within these areas.